Optimize Manufacturing Process With Content Services Platform

1. Difficulty of manufacturing process

The manufacturing process can be complex and multifaceted, presenting various challenges that manufacturers must navigate. One significant difficulty is maintaining consistent quality standards throughout production. Achieving uniformity in output, especially in mass production, requires meticulous attention to detail and adherence to strict protocols. Another challenge is optimizing efficiency while minimizing costs. Balancing factors such as labor, materials, and equipment utilization to maximize productivity without sacrificing quality is a constant juggling act. Additionally, managing supply chain logistics poses a difficulty, particularly in sourcing raw materials, coordinating with suppliers, and ensuring timely delivery to meet production schedules. Regulatory compliance is yet another challenge, as manufacturers must adhere to a myriad of industry standards and regulations to ensure product safety and legality. Lastly, staying abreast of technological advancements and market trends to remain competitive in an ever-evolving landscape presents a continuous challenge for manufacturers. Overall, overcoming these difficulties requires strategic planning, innovation, and adaptability to thrive in the manufacturing industry.

2. How to optimize it?

Optimizing the manufacturing process involves implementing strategies to enhance efficiency, quality, and overall performance. Here are some key steps to optimize manufacturing processes:

- Streamline Operations: Identify and eliminate inefficiencies in workflows, such as redundant tasks, bottlenecks, and unnecessary steps. Streamlining operations reduces waste and improves productivity.

- Invest in Automation: Integrate automation technologies, such as robotics, IoT devices, and AI-driven systems, to automate repetitive tasks, minimize human error, and increase throughput. Automation can also improve consistency and quality control.

- Utilize Lean Manufacturing Principles: Implement lean manufacturing principles, such as 5S (Sort, Set in order, Shine, Standardize, Sustain) and Kaizen (continuous improvement), to identify and eliminate waste, optimize resource utilization, and enhance workflow efficiency.

- Optimize Supply Chain Management: Strengthen supply chain management processes by fostering collaboration with suppliers, implementing demand forecasting techniques, and adopting advanced inventory management systems to ensure timely delivery of materials and components.

- Embrace Just-in-Time (JIT) Manufacturing: Adopt JIT manufacturing practices to minimize inventory holding costs, reduce lead times, and improve responsiveness to customer demand by producing goods only as needed.

- Implement Total Quality Management (TQM): Integrate TQM principles to promote a culture of quality throughout the organization, focusing on continuous improvement, defect prevention, and customer satisfaction.

- Invest in Employee Training and Development: Provide comprehensive training programs to enhance employee skills, knowledge, and proficiency in manufacturing processes and technologies. Empowered and skilled employees contribute to improved productivity and innovation.

- Harness Data Analytics: Leverage data analytics tools and techniques to gather actionable insights from manufacturing data, optimize production processes, identify trends, and make data-driven decisions to drive continuous improvement.

- Regular Maintenance and Equipment Upgrades: Implement proactive maintenance schedules to prevent equipment breakdowns and downtime, ensuring optimal equipment performance. Additionally, invest in upgrading machinery and technology to stay competitive and efficient.

- Continuous Improvement: Foster a culture of continuous improvement across the organization, encouraging employees to identify and implement innovative ideas to enhance manufacturing processes, quality, and efficiency.

By implementing these optimization strategies, manufacturers can streamline operations, improve productivity, reduce costs, and ultimately enhance their competitiveness in the market.

3. DocuWare will help you to optimize manufacturing process

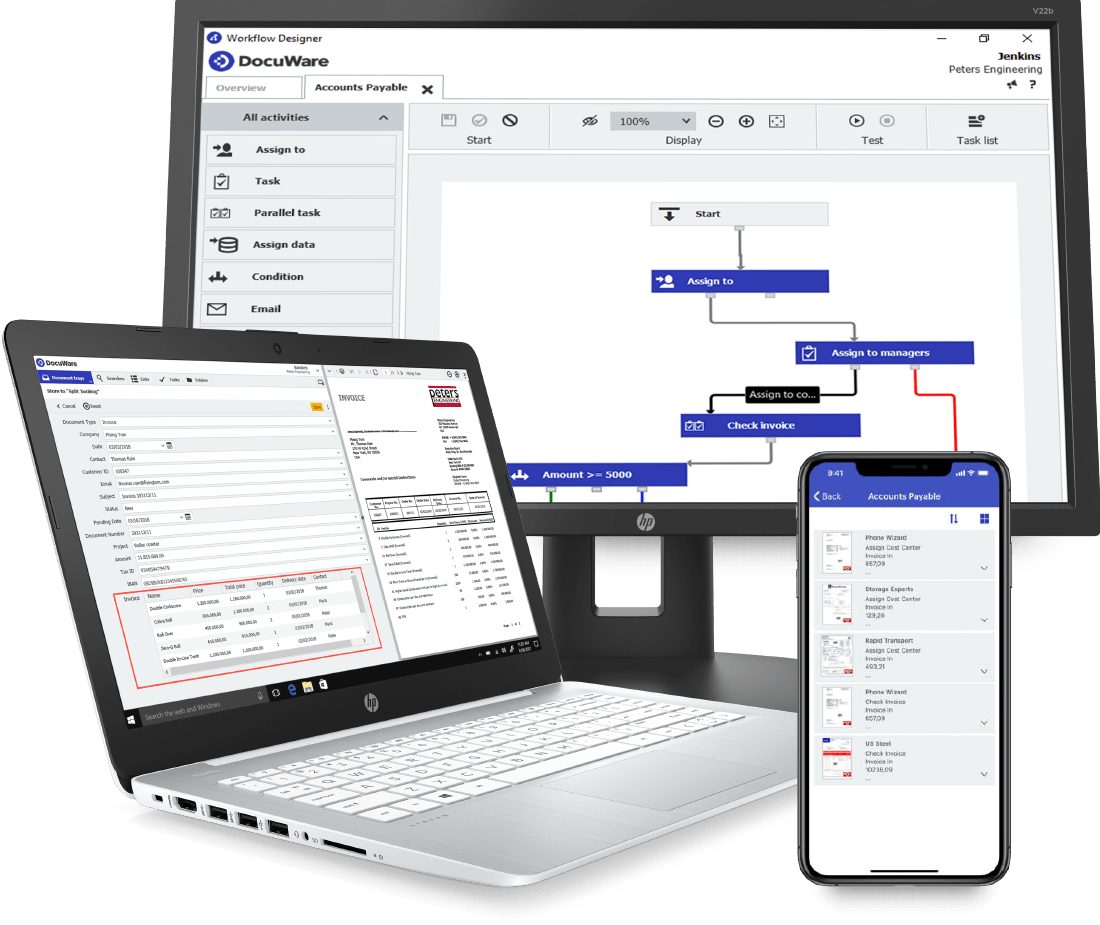

DocuWare is a comprehensive, feature-rich content services platform that has the capability to transform cluttered paper documents into secure and easily searchable digital information. It also converts tedious manual processes into engaging and automated digital workflows.

Absolutely, DocuWare offers several features and functionalities that can contribute to optimizing manufacturing processes:

- Document Management: DocuWare streamlines document management by digitizing paper-based processes, allowing manufacturers to store, organize, and access documents efficiently. By digitizing documents, manufacturers can reduce the time spent searching for information, minimize errors, and improve collaboration among team members.

- Workflow Automation: DocuWare's workflow automation capabilities enable manufacturers to automate repetitive tasks, approvals, and notifications. By automating workflows, manufacturers can improve process efficiency, reduce manual errors, and ensure consistent adherence to standard operating procedures.

- Intelligent Indexing: DocuWare's Intelligent Indexing feature uses artificial intelligence (AI) to automatically extract key information from documents, such as invoices, purchase orders, and quality control reports. This reduces the need for manual data entry, speeds up document processing, and improves accuracy.

- Integration with ERP Systems: DocuWare integrates seamlessly with enterprise resource planning (ERP) systems commonly used in manufacturing, such as SAP, Oracle, and Microsoft Dynamics. This integration enables manufacturers to synchronize data between DocuWare and their ERP systems, streamlining processes and ensuring data consistency across the organization.

- Version Control and Audit Trails: DocuWare provides version control and audit trail capabilities, allowing manufacturers to track changes made to documents over time and maintain a record of document revisions. This ensures compliance with regulatory requirements and provides transparency into document history.

- Mobile Access: DocuWare offers mobile applications that enable manufacturers to access documents and workflows from anywhere, at any time, using mobile devices. This facilitates remote collaboration, accelerates decision-making, and enhances productivity for mobile workforce.

- Data Analytics and Reporting: DocuWare's reporting, and analytics tools provide manufacturers with insights into document-related metrics, such as document processing times, workflow bottlenecks, and document retrieval rates. This data-driven approach enables manufacturers to identify areas for improvement and optimize their document management processes.

News & Events

Keep up to date

- 18Dec

Ricoh recognised as a Top 5 global AV Integrator in SCN Top 50 Systems Integrators 2025

- 11Dec

Ricoh Recognised as a Sustainability Leader in Quocirca's 2025 Report

- 07Nov

Ricoh Pro C7500 Gold Toner Brings Sustainable Luxury to Sun PhuQuoc Airways’ Travel Guide

- 31Oct

Ricoh perovskite solar cells installed on Japan Aerospace Exploration Agency cargo transfer spacecraft1 HTV-X1