Part 1: Key Trends for 2025

Global Perspective

According to Maersk, 7 criteria related to warehouse and distribution management will be emphasized globally in 2025:

- Space Availability: This reflects the ability to provide wide-scale storage services, supporting businesses' regional flexible business strategies. This stems from brands' and retailers' cautious behavior in maintaining lower inventory levels.

- Automation: Automation appears to be a mandatory element in warehouse management, demonstrated through continuous updates of new technologies and optimization of warehouse management metrics. This factor will continue to receive special attention in 2025, particularly in expanding logistics operations for large companies.

- Maintenance Costs: These directly correlate to warehouse owners and users, with costs included in anticipated maintenance agreement budgets. Typically, these costs are minimal for rack systems, supports, and pallets designed for at least 20 years of use, while automated systems and equipment require more maintenance resources, replacement, and updates.

- Single stock holding vs. forward-deployed stock: This relates to business inventory strategy when considering between centralizing stock at a major point for omnichannel distribution (online to offline) versus choosing distribution based on a forward-deployment model with smaller inventory quantities across multiple locations, bringing their goods closer to target markets.

- Connected Inventory: A warehouse system connected across the entire network or globally for large enterprises offers advantages not only in executing high-level strategy and understanding customer needs but also in detecting changes in enterprise goods circulation.

- Global fulfillment for multiple solutions: Focus on global collaborative relationships rather than investing in building single-purpose warehouses. This factor will help businesses access, penetrate, and conquer markets through multiple approaches.

- Towards bigger and better: Warehouse scale factors will continue to increase in both storage space (over 100,000 square meters) and faster computer systems. Inventory control systems will be updated to link retail store sales with new warehouse supply capabilities through modern order management systems.

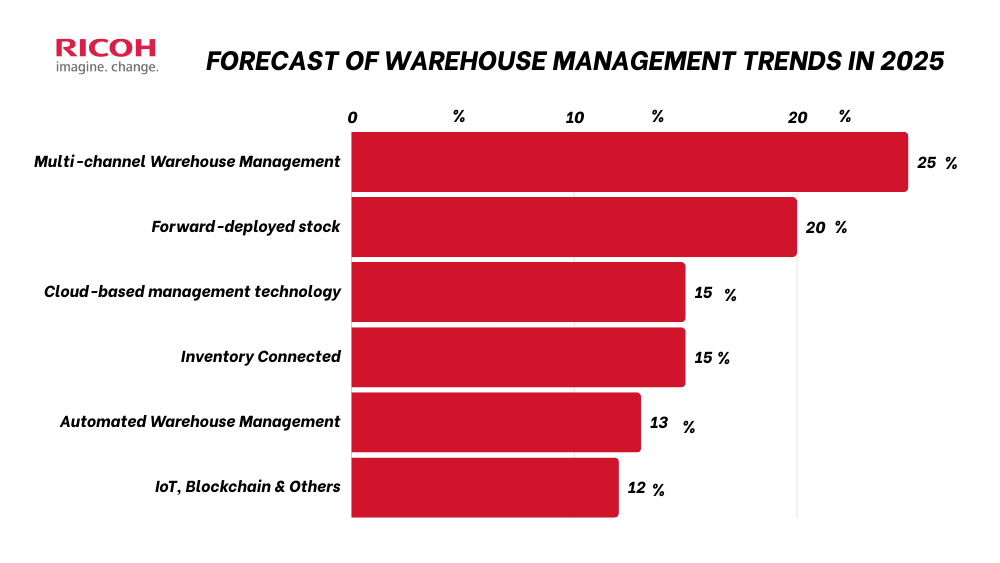

In Vietnam

Sharing a similar perspective with Maersk, Ricoh also forecasts warehouse management trends, though with some variations based on Vietnam's specific situation.

Generally, forecasts indicate that 2025 trends will continue and evolve alongside new technologies and solutions being implemented. There are two main reasons for this:

- First, warehouse management requires significant capital investment with extended return periods. Given the economic downturn, businesses are extremely cautious about implementing any new solutions.

- Project cycles are very long, typically taking 2-3 years to see results from specific trends.

Nevertheless, forecasts suggest these factors won't prevent modern technologies and new software from being deployed and tested in warehouse management.

Read more about Warehouse Management Trend in 2024

Part 2: Opportunities and Challenges

Opportunities

- E-commerce Growth: According to the Government Electronic News Portal, Vietnam's e-commerce market reached $25 billion in 2024, up 20% from the previous year, accounting for 9% of total national retail and service revenue. This creates substantial demand for warehouse and logistics services to meet businesses' rapid delivery requirements.

- Global Supply Chain Shift: According to VietnamNews, this issue originated after the COVID-19 pandemic and was escalated by regional conflicts and, most recently, US-China geopolitical tensions. Many companies view Vietnam as a new "promised land" for headquarters, benefiting various economic sectors including warehouse management.

- Digital Technology Adoption: As analyzed in section 2.2, numerous technologies have been, are being, and will be implemented in the warehouse management industry.

- Infrastructure Development: According to VNExpress, the country currently has about 2,021 km of highways, with an additional 1,200 km planned for 2025 and 5,000 km by 2030. Additionally, Cai Mep Port (Vung Tau) and Long Thanh International Airport (Dong Nai) are under urgent construction, contributing to the dynamic development of logistics and warehouse management.

Challenges

Warehousing service businesses face numerous challenges, with these three being most prominent:

- Competitive Pressure: Major corporations like DHL, Maersk, and Geodis are planning investment expansions, alongside e-commerce platforms like Shopee Express expanding into warehousing operations. This forces warehouse management service providers to modify business strategies and modernize processes.

- High Investment & Operating Costs: The warehousing industry has unique characteristics with high investment costs and extended break-even periods of 2-3 years, requiring companies to have both strong resources and appropriate business operation strategies.

- Rapid Technological Changes: As mentioned above, warehousing projects require extended investment periods. Therefore, choosing appropriate operational models and technologies must be carefully considered to avoid obsolescence before implementation.

Part 3: Recommended Warehouse Technologies

Aligned with TrendsTo visualize warehouse operations and maximize storage capacity, the following technologies will help you leverage and stay ahead of warehouse management trends:

Smart Picking Tools

Implementing automation and smart machinery for transportation and logistics helps achieve accurate sorting and reduces transportation time for large volumes of packages. Currently, two types of smart picking tools are being used by warehouses and distribution centers:

- First, automated conveyor systems

- Second, automated picking robot systems such as Autonomous Mobile Robots (AMR) or Automated Guided Vehicles (AGV)

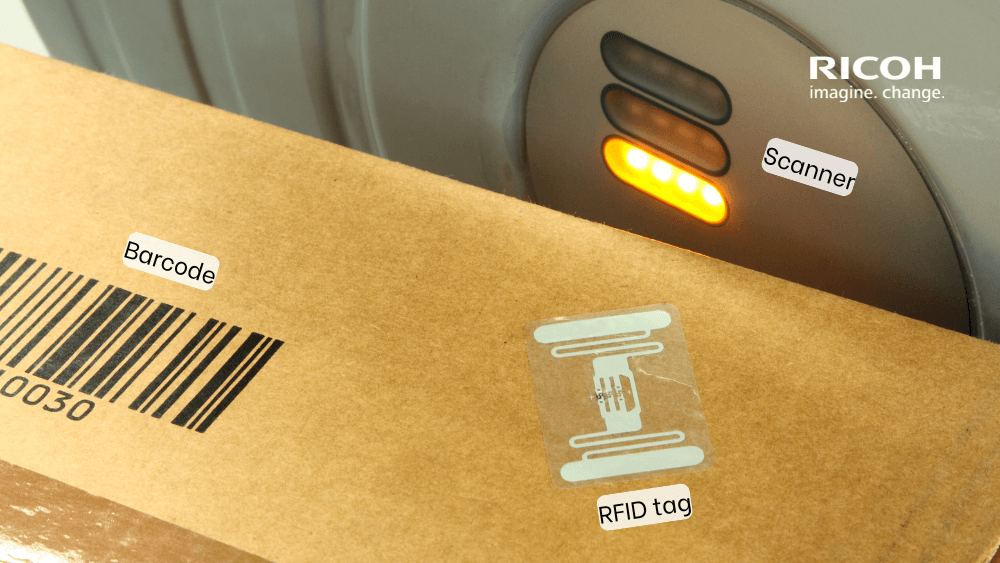

These devices typically feature fast movement speeds and high load capacity, making them particularly effective when integrated with automatic identification systems like barcodes or RFID for rapid and accurate sorting.

Automated Storage and Retrieval Systems (AS/RS)

This modern solution automates warehouse storage and retrieval operations. Previously considered expensive and inflexible to operate, technological advancement has now provided more options to reduce manual labor while ensuring complete and accurate storage.

To optimize this system, the core priority should be comprehensive warehouse management and accuracy assurance, thus integration with WMS and automatic identification systems using barcodes or RFID is recommended.

Data Transformation Technology

Data transformation technology leverages the intelligence of technologies like AI, blockchain, and IoT for systematic, accurate, and secure information storage.This technology helps businesses optimize costs for documentation departments and IT teams while ensuring product-related data remains complete, accurate, and secure.

Currently, this is also the first factor businesses consider when looking to transform into a "smart" warehouse.

Inventory Scanning Technology

As mentioned, barcodes and RFID are two technologies that have emerged and continue to be widely trusted in Vietnam. While RFID helps speed up identification processes, barcodes will always be necessary as a parallel backup or replacement solution if RFID becomes ineffective, such as in wet environments or areas with signal interference.

However, when implementing this technology, businesses should consider integrating warehouse management systems and smart data transformation for maximum effectiveness.

Find now Comparison between Barcode and RFID

Recording Technology

This technology ensures information tracking across receiving, inventory, and shipping operations, providing insights into warehouse operations to optimize performance. These records create a foundation for other solutions like origin tracing and warehouse network connectivity. Additionally, recording technology helps businesses measure and proactively plan merchandise purchases.Currently, smart recording is being initially implemented in automated warehouses in Vietnam.

Part 4: Conclusion

Warehouse management – the crucial logistics component helping businesses succeed in sales. An effective warehouse management process will operate all stages quickly while optimizing investment resources and reducing operational costs, thereby helping businesses maximize profits.

Understanding which new effective warehouse management methods and technologies have been, are being, and will be applied is also a way for businesses to be more proactive in building their business models.

Are you ready to update your warehouse management technologies?

Discover more about the warehouse management methods and establish new technologies now.

Chat via Zalo

Let’s connect

Get in touch with one of our consultants and find out how we can help you to implement a barcode system

Recommended resources for you

.png)

Things You Should Know About Warehouse Management in 2024

Discover the top trend of warehouse management in 2024

Direct Thermal or Thermal Transfer: Which One To Choose?

This article will provide step-by-step guidance to help you navigate the world of thermal printing technology.