Introduced to the market in 1989 and persisting through over 35 years in the thermal transfer materials industry, the B110A Wax Resin thermal transfer ribbon has become one of the flagship products in Ricoh's industrial printing solutions business.What value has B110A brought to users that has enabled such sustainable longevity? The answer will be revealed later in this article.

Part 1: Understanding Wax Resin and B110A

What is Wax Resin Ribbon?

Wax Resin ribbon is a type of ribbon composed of two main components: Wax and Resin, positioning it in the intermediate segment between Wax and Resin ribbons. This ribbon type combines the advantages of both components: the thermal sensitivity and density of Wax along with the relative durability of Resin. As a result, Wax Resin ribbons not only provide cost optimization but also ensure better resistance compared to pure Wax ribbons.Wax Resin ribbons are most suitable for applications that don't involve frequent exposure to harsh conditions such as high temperatures, strong friction, or highly corrosive chemicals.

This makes them an ideal choice for printing needs that require consistent quality at a reasonable cost.Other popular Wax Resin grades from Ricoh include: B120E, B110A, B115A, B110TI, B110Z, and more.

B110A Wax Resin – A Market-Leading Product

According to Ricoh's business data, nearly one-third of the total finished ribbon rolls distributed in Vietnam belong to the B110A Wax Resin line, equivalent to over 70 million meters of ribbon used. To put this in perspective, this total length could wrap around the Earth's circumference almost twice.With this impressive consumption rate, B110A can definitively be called Ricoh's best-selling product line in the Vietnamese market. This demonstrates not only its popularity but also users' trust in the product.What factors have established B110A's reputation in the barcode ribbon market over the past 35 years? The answer will be revealed in Part 2.

Part 2: Factors That Make B110A Stand Out in the Ribbon Market

Premium Wax Resin in the Market

Structure of common printing ribbons in the market:

- Wax Ribbon: Typically has 2 layers (base film and ink)

- Wax-Resin Ribbon: Typically has 3 layers (base film, ink, and protective coating), offering moderate durability

- Resin Ribbon: Typically has 3 layers (base film, ink, and protective coating), providing resistance to strong chemicals or harsh conditions beyond Wax Resin capabilities

Uniquely, all ribbon types developed by Ricoh feature a 5-layer structure that protects the printhead, enhances long-term printing stability for high-volume operations, and provides protection against static electricity.

B110A Printer Compatibility

The B110A Wax Resin barcode ribbon is designed to be compatible with most modern barcode printers in the market, including Zebra, Sato, Toshiba, Honeywell, Datamax, and others. This wide compatibility meets diverse printing needs and seamlessly integrates with existing enterprise printing systems.

When selecting a ribbon, a crucial consideration is the printhead technology. Currently, two types dominate the market: Near-Edge and Flat Edge printheads. While B120E is specifically designed for Near Edge printing systems, B110A is the perfect choice for barcode printers using Flat Edge technology.

Ricoh will publish a detailed article on this topic - leave your email to receive related updates.

Another significant advantage of B110A over other market ribbons is its operational stability. The B110A barcode ribbon maintains stable performance even on high-speed printers, minimizing printhead wear - a common issue with lower-quality ribbons.

An additional noteworthy feature of B110A is its thermal sensitivity, with a melting point of 84°C, considered quite "printhead-friendly" compared to other ribbons in the same segment that require 85-88°C for printing. This lower temperature reduces wear and extends printhead life, resulting in significant maintenance cost savings.

Print Image Quality

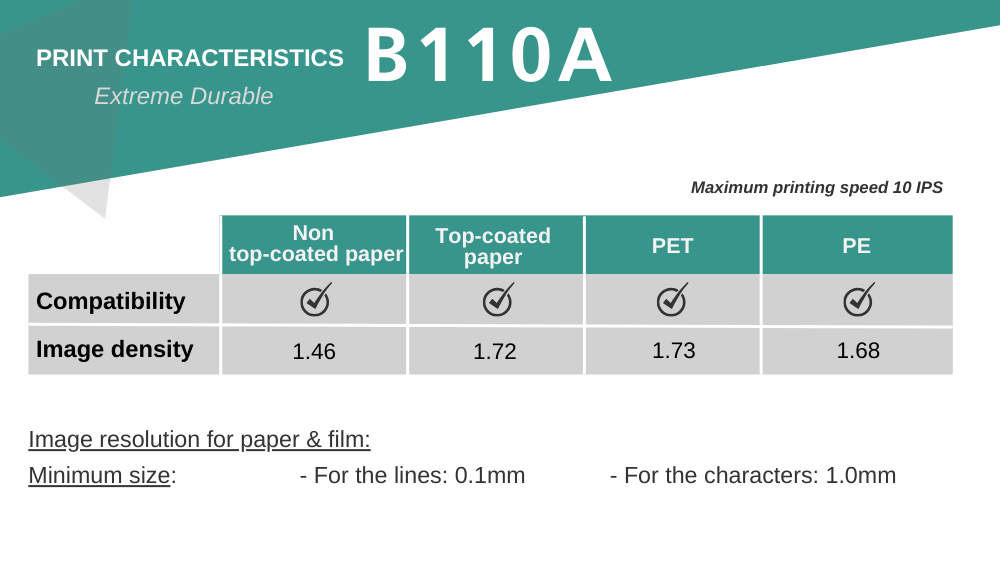

Surface Compatibility

This is seemingly the minimum requirement for a quality ribbon and is often the first requirement customers mention when approaching ribbon suppliers. A ribbon with good compatibility minimizes issues like ink slippage, smudging, and poor adhesion, ensuring clear prints that last longer.

As a Wax Resin grade ribbon, B110A contains both wax and resin particles in its composition, enabling printing on surfaces such as paper, coated paper, or synthetic materials like PET, PE, and PP.

Some materials Ricoh recommends for use with B110A ribbon include:

- Semi-gloss Paper: AW0331

- Gloss Paper: AW0153

- Matte Paper: MW0052, MW0066

- Matte BOPP: BW0153

- Gloss BOPP: BW0227

- PET: MZ0102

Print Density

The most noticeable aspect of printed images is density. Typically, Wax-grade ribbons provide good density on paper surfaces due to their high absorption rate on these materials. Conversely, Wax Resin and Resin ribbons produce denser images on synthetic surfaces like PP, PE, and PET. This parameter can also be adjusted through printhead temperature, pressure, and print speed.

B110A is rated as having excellent print density, as demonstrated in the reference image below:

Print Resolution

With B110A, users can print clear characters as small as 0.1mm for lines and 1mm for characters. Both density and resolution parameters affect the readability of images by scanning devices. The appropriate ribbon type should be selected based on the application, which will be discussed in Part 3.

Color Options

Blue and Red

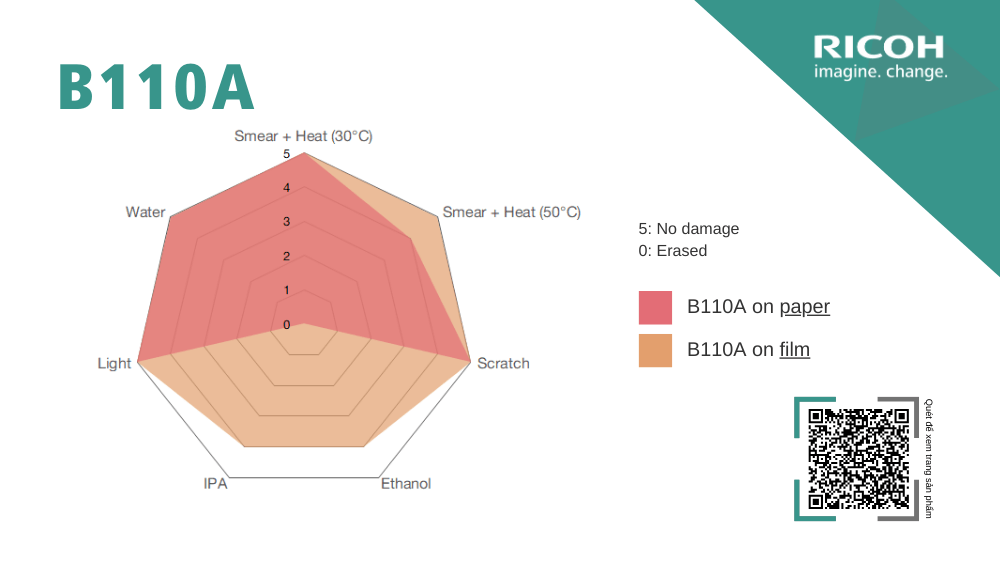

Print Durability

Ricoh's data shows the durability rating (1-5) of images printed with B110A on both paper and film surfaces when exposed to physical impacts, environmental factors, and chemicals.

For printed images, based on the ANSI 1-5 scale, we can better understand the durability of images printed with B110A ribbon when tested under various conditions.

Test Conditions:

- Heat friction smudge at 30°C

- Heat friction smudge at 50°C

- Scratch resistance

- Ethanol resistance

- IPA resistance

- Light resistance

- Water resistance

Performance on Film Materials

When printing on film materials, B110A demonstrates excellent durability with scores of 4-5 points across various conditions. The printed images show particular resistance to:

- Light exposure (5/5)

- Water contact (5/5)

- Heat smudge resistance (30-50°C) (4-5/5)

- Scratch resistance (4/5)

- IPA, Ethanol resistance (4/5)

Performance on Paper Materials

When used with paper labels, this Wax Resin ribbon shows strong resistance against:

- Light exposure

- Water contact

- Heat smudge at 30°C

- Scratch resistance

For applications involving direct contact with common cleaning agents like IPA or Ethanol, users should consider using film materials instead of paper. B110A achieves a score of 4/5 for chemical resistance when printed on film surfaces.

View B110A Product Page for More Details

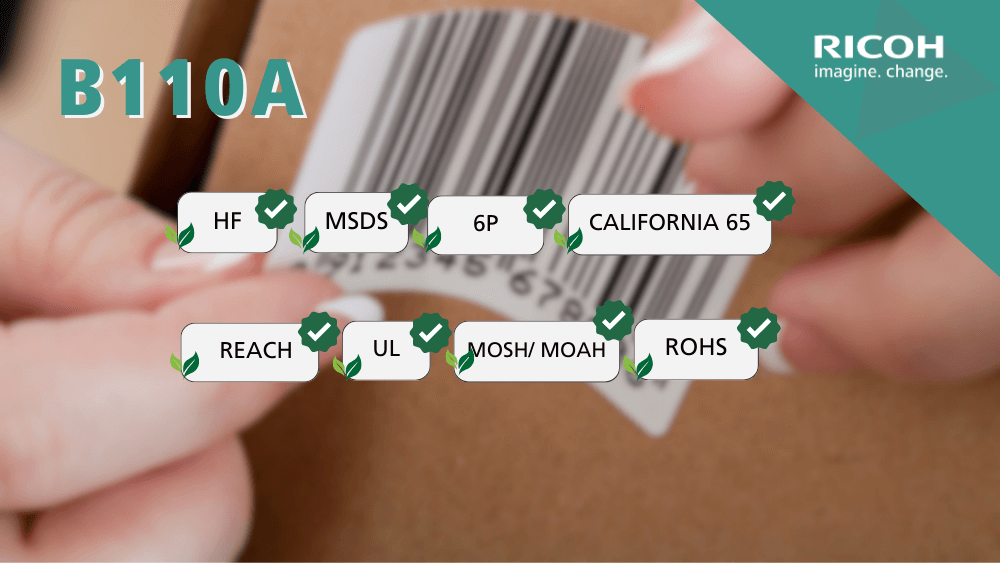

International Certifications/Strict Compliance

As Vietnam's export industry continues to grow rapidly, businesses are increasingly standardizing their products to meet consumer market requirements. Major markets known for their "strict" regulations that Vietnamese businesses are targeting include Europe, the United States, and Japan. B110A has obtained several certifications to meet these requirements.Some of B110A’s certificates:With its impressive portfolio of certifications, B110A can give businesses greater confidence in choosing an appropriate label printing solution. Here are some key applications of B110A:

| Name | Stand For | Details |

| MOAH/MOSH | Mineral Oil Aromatic Hydrocarbons & Mineral Oil Saturated Hydrocarbons | MOH-free certification - Product contains no mineral oil-based compounds |

| RoHS | Restriction of Hazardous Substances | European compliance certification for hazardous substances regulations (Pb, Hg, Cd, Cr6+, PBB, PBDE) |

| REACH | Registration, Evaluation, Authorization, and Restriction of Chemicals | EU compliance certification covering approximately 200 chemicals |

| UL | Underwriters Laboratories | UL safety standards certification for products sold in North America |

| HF | Halogen Free | Compliance with Halogen compound regulations (Br, Cr, F) |

| MSDS | Material Safety Data Sheet | Reliable reference point for material safety through MSDS prepared by manufacturer or material supplier |

| 6P | Six Principal | FDA certification confirming compliance with 6 safety and hygiene principles |

| California 65 | California Proposition 65 | OEHHA (US) certification meeting chemical content limits for lead, cadmium, total phthalates, and bisphenol A |

Part 3: Suitable Applications

Ready To Explore B110A And Try It On?

Discover more about the B110A’s widespread applications and benefits.

Chat via Zalo

Let’s connect

Get in touch with one of our consultants and find out how we can help you to implement a barcode system

Recommended resources for you

.png)

Things You Should Know About Warehouse Management in 2024

Discover the top trend of warehouse management in 2024

Direct Thermal or Thermal Transfer: Which One To Choose?

This article will provide step-by-step guidance to help you navigate the world of thermal printing technology.

_transparent.png?h=860&iar=0&w=860&hash=B1A24680F9BBC6BA7EBFBD18CB0C35C6)