Barcode Labels in the Electrical and Electronic Industry

Barcode labels play a crucial role throughout the supply chain of the electrical and electronic industry, from raw material sourcing to the hands of consumers. They facilitate real-time inventory control, efficient warehouse management, error prevention in material picking, automated data handling, swift information retrieval, and enhanced customer responsiveness. However, ensuring the readability of barcode labels in the electronics industry remains challenging, as these identification labels must endure high temperatures, exposure to chemicals, and other harsh conditions during production. This article will shed light on the applications of labels in manufacturing and the proposed solutions from Ricoh.

Loss of label information can render barcodes unreadable

Identification labels used in managing the manufacturing processes of electrical components and electronic devices often go through multiple stages under harsh conditions, including direct contact with alcohol and cleaning chemicals, high-temperature environments such as soldering with temperatures ranging from 180°C to 190°C, and friction with hard surfaces during assembly and machine operation. These factors can compromise the integrity of the label information and result in barcodes that specialized devices cannot read. Consequently, the information retrieval process is disrupted, affecting various stages from product identification and assembly to quality inspection, packaging, transportation, and maintenance.

Low-resolution image when printing multiple types of information simultaneously: text, horizontal barcodes, ladder barcodes

The specific requirements of labels used in the electronics industry, with small sizes and the need to include multiple types of information on a single label (such as characters, horizontal barcodes, vertical barcodes, and QR codes), often exceed the capabilities of standard labels and printing inks in terms of readability. This can affect barcode scanning, automated data handling, and source tracing capabilities when issues arise.

Stringent quality requirements apply not only to products but also to information labels

Most countries, including Vietnam, impose strict regulations on the information displayed on labels and the materials used, ensuring they do not contain hazardous substances that could harm human health or the environment. Below are some standard certifications required for labels:

| Certificate | Stand for | Content |

| RoHS | Restriction of Hazardous Substances | Certification that products sold in Europe do not contain hazardous substances |

| REACH | Registration, Evaluation, Authorization, and Restriction of Chemicals | Certification that products sold in Europe do not contain hazardous chemicals |

| UL | Underwriters Laboratories | Certification ensures that products sold in North America meet UL's safety standards. |

| WEEE | Waste Electrical and Electronic Equipment | Certification thatproducts sold in Europe meet the environmental protection standards by cutting waste from electrical equipment. |

Typical applications of labels in the electrical and electronic industry

PDC board labels PDC board labels |

Electronic accessories and spare part labels Electronic accessories and spare part labels |

Nhãn số serial với resin trắng Nhãn số serial với resin trắng |

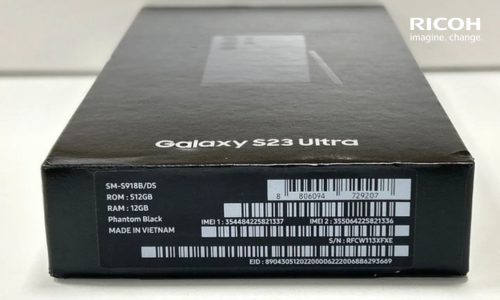

Nhãn hộp điện thoại Nhãn hộp điện thoại |

Label Requirements in the Electrical and Electronic Industry

Based on the actual manufacturing environment, barcode labels need to be durable in external conditions such as

- Withstand temperatures of up to 200°C

- Resistant to chemicals such as IPA and alcohol during component cleaning

- High resolution, capable of printing fine details and minor characters

- In addition, they need to achieve various quality, environmental, and emissions certifications: TSAC-F, RoHS, WEEE, EU, AEO, REACH, and MSDS.

Recommended Products from Ricoh

With Ricoh's Resin Ribbon B110CR and B110CU combined with materials like PVC, PP, PET and special receiving materials from Ricoh, you can have a specialized barcode label solution for the electrical and electronic industry with the following features:

- Capable of withstanding temperatures from 200°C to 250°C

- Resistant to chemicals such as alcohol, IPA, gasoline, and machine oil while also having good scratch resistance

- High resolution, even when using 300 dpi and 600 dpi print heads

- UL certification

- Reduced static electricity due to ink peeling off

In Conclusion

In the electrical and electronic industry, using barcode labels is an intelligent solution that simultaneously addresses various issues and improves processes. This encourages many businesses to seek and desire to apply barcode technology. However, choosing the right approach is a strategic step, and business owners need a clear understanding to ensure that their investment costs deliver full effectiveness. For guidance and support in choosing the most suitable barcode label printing solution, please get in touch with Ricoh IMS Vietnam via [email protected] or +84 28 3528 5252.

News & Events

Keep up to date

- 13Mar

Ricoh named in “Clarivate Top 100 Global Innovators 2025” list

- 06Mar

Ricoh ranked 39th in Carbon Clean200™ 2025 list

- 17Feb

Ricoh selected as a member of the Sustainability Yearbook 2025 by S&P Global

- 14Feb

Ricoh recognized with double ‘A’ score for climate action and water security leadership in CDP A List for two consecutive years